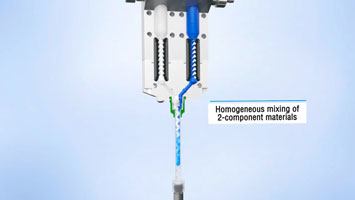

The 2-component print head vipro-HEAD, for three-dimensional printing of two-component fluids and pastes, in video: And that when printing a 2-component silicone. The high-precision process becomes clear based on real components.

Screenshot from the new video about the 2-component Print Head from ViscoTec.

At the beginning of the video, the endless piston principle is explained and how the 2-component materials are homogeneously mixed. Then special features of the print head are explained in more detail. The parallel and independently running motors receive signals directly from the 3D printer. An adapter with venting screws is available as an option to facilitate venting during commissioning. As well as integrated pressure sensors for automatic safety shutdown if required. For optimal mixing of the 2-component material, a wide range of static mixers can be attached to the print head.

A big advantage of the ViscoTec technology: Material quantity and dosing speed can be individually adjusted for absolutely flexible 3D printing processes. The automatic retraction at the end of the dosage ensures a defined thread break and thus guarantees a high-quality printing result. The print head can be used flexibly for a wide variety of applications. The range of materials that the vipro-HEAD can dose is also broad: Silicones, polyurethanes or epoxy resins, to name just a few.

You can find further information about 3D printing of fluids and pastes with ViscoTec technology here.

The new video:

The post Application Video About 2-component Print Head vipro-HEAD appeared first on ViscoTec Pumpen- u. Dosiertechnik GmbH.